In Part 1 we pointed out that implementing an ERP system for manufacturing allows companies to integrate business functions, streamline processes, and use automation to reduce wastage and costs, and improve productivity and efficiency.

We covered the importance of identifying the business goals of the project, and setting up a project organization. In Part 2, we explain the phases of the implementation project.

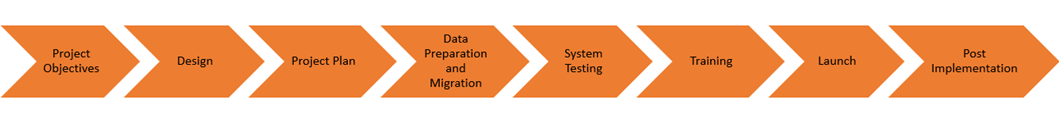

The ERP implementation phases

There are nine phases that an ERP implementation project should follow.

Phase 1: Project objectives

The objectives of the ERP implementation help to create the roadmap of the project, ensuring that priorities are set and each step of the project aligns with the desired business objectives.

Phase 2: Design

Unless you have staff who have implemented an ERP project before, this is the phase that will require an ERP implementation partner.

The design phase takes the results of Phase 1 (objectives, priorities, etc) to develop a detailed functional design of how the ERP system will enable new processes and workflows from an end-user perspective.

This is where the decision is made on whether the system can be used ‘as-is’ with some configuration, or if major changes — customization — will be needed, and if integration with third-party software is required.

Customization entails changing an ERP system’s source code or functionality to satisfy unique business needs so that the ERP matches the business. Configuration is a more adaptable option. It allows changes to the system’s parameters and settings without altering the underlying code. It makes use of the system’s built-in tools, interfaces, and capabilities. It makes updates easier and quicker.

Phase 3: Project plan

Once the project objectives and design are set, the ERP project plan can be established, with timelines, budgets and resources needed.

The project manager uses the project objectives and the design specifications to build a project plan. He manages the implementation project to ensure everyone works together and assigns resources as and when required during the project. Without proper planning by an experienced project manager, the project can experience unexpected delays and expenses. Clear project timelines, goals and budget keep the implementation on track and minimizes the likelihood of major problems and even failure.

Phase 4: Data Preparation and Data Migration

This step takes the company’s existing data, usually from legacy systems, and analyses and validates it to eliminate errors and duplication. The data is then transferred into the new ERP system. There should be clear data mapping rules and a robust means of validating the data as it is loaded.

This is a crucial step in the implementation because the accuracy and integrity of data directly affect the effectiveness of the system.

Phase 5: Implementation

Implementation is typically what people think of when it comes to an ERP system for manufacturing. Here the ERP application is developed, including chart of accounts, business units and cost centers. The ERP system’s modules are also set up, such as financial management, inventory management, production and sales, including the processes that will be followed. User roles and permissions are established to regulate access control for security purposes.

The project team is involved in verifying that the development is proceeding appropriately. This is also when stakeholders start to become acquainted with the way the system will work within the business.

Phase 6: System Testing

System testing is crucial in identifying issues that could negatively impact the ERP implementation. It helps to identify potential issues before the system is implemented. All the ERP components and processes are evaluated in this phase. The accuracy of migrated data is also verified. This phase is where security testing needs to be done to ensure data is protected and access authorization works properly.

Testing is a process that includes various tests such as unit testing, system testing, integration testing, and user acceptance testing.

A comprehensive testing plan will test processes thoroughly and should cover all aspects of the ERP system. Any issues identified during the testing phase should be documented and addressed before the system goes-live. This is also when the steering committee will see if the new system meets objectives and requirements.

Phase 7: Training

The training phase is an essential element to help the end users of the ERP system learn to use it effectively. It prevents errors due to misunderstandings. Well-trained employees will understand the ins and outs of the system and help boost their productivity. Training minimizes resistance issues to the project, establishing a smooth transition from the old legacy system to the new ERP solution.

A training plan should include:

- how the ERP system operates and its associated business functions;

- a step-by-step guide on how to use the different features and functions of the system;

- details on data entry, reporting and other basic tasks;

- guidance on how to troubleshoot common issues.

Different training methods can be used — such as classroom sessions, online tutorials and hands-on exercises.

Phase 8: Launching the System

In an ERP implementation, the launch, or go-live, is the most anticipated phase.

A well thought-out launch plan can help the go-live run smoothly. The plan should include a communication strategy to keep all the stakeholders informed and a contingency plan for addressing issues that may arise. In this phase, the ERP project team plays an important role in addressing questions, providing guidance and resolving technical issues.

There are two options for a launch — a phased rollout or full deployment (sometimes called a big bang). In the phased rollout, the ERP system is introduced in stages in specific areas before it is implemented in the broader organization. A full deployment involves launching the ERP system throughout the organization at the same time.

Phase 9: Post-Implementation Evaluation and Support

The ERP implementation does not end at the launch. The post-implementation phase is equally important. It involves monitoring the performance, addressing any issues that arise after launch, and providing ongoing support to users.

This is where the ERP solution is evaluated to determine how it has met the organization’s objective and the impact on user productivity and satisfaction.

Ongoing user training and support is important, in particular when the system is upgraded and new functionalities are added.

Updates are also crucial to keep the ERP solution aligned with evolving requirements, and to fix any security vulnerabilities and performance issues.

ERP Continuous Improvement

The reason that an ERP system for manufacturing is implemented is to improve existing operations. Unfortunately, some people think that once the ERP system has gone live then the project is finished.

By employing the ‘Kaizen’ method of continuous incremental improvement, an ERP system can keep delivering benefits to the organization, as external situations like market trends and production technology changes. Internally, Kaizen creates a culture where all employees are engaged in suggesting and implementing improvements. This will avoid the scenario when you discover that the business has changed but the ERP system no longer supports it.