All industries have their unique aspects which is why it is so important to select an ERP system that caters to your business’s specific challenges. For example, an ERP for automotive distributors needs to include not just a standard sales function but also allow for automotive-specific processes like call-offs and contract pricing, as well as other processes like returns and lot traceability. There are several business processes that an ERP must have to support automotive distribution.

What is automotive distribution?

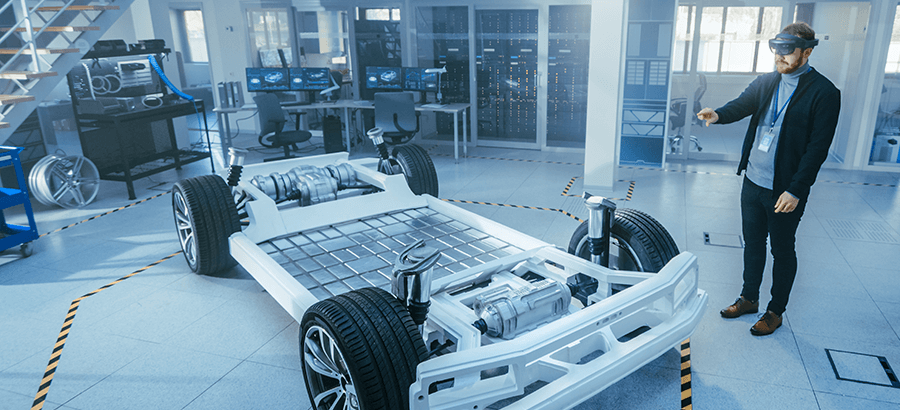

Automotive distributors play a vital role in the automotive supply chain by procuring parts, warehousing them, and then supplying them to OEMs (original equipment manufacturer), retailers or end consumers.

Why is an ERP important?

An ERP system is a valuable asset for automotive distributors looking to leverage the data they create and use. An ERP provides a central repository for all a distributor’s data. The data can be used to identify inefficiencies in the supply chain, improve inventory management, and streamline operations. Data can also be used to generate reports and insights that can help distributors improve their business regarding everything from pricing and product selection to marketing and sales strategies.

Eight key processes of automotive distributors

Automotive distributors have specific processes that need to be optimized and streamlined.

- Supply chain management

The international sourcing of automotive components is now a common practice but it can still present challenges. To avoid this, distributors need an ERP that gives them visibility across the supply chain by tracking materials from source through to final destination.If a customer’s requirements change, an ERP for automotive distributors should be able to respond quickly by alerting trading partners and value-added networks via automated data interchange.As recent events have shown, the automotive industry is vulnerable to supply chain disruptions, such as shortages of components or delays in delivery. Using a supplier portal, distributors can mitigate these risks by quickly checking where alternative parts can be sourced. A supplier portal can also be used to request information from suppliers on materials and costs and place orders without having to wait for paperwork or emails to confirm orders.

- Inventory management and warehousing

Thousands of parts are used in automotive distribution. To manage this large volume of inventory requires an inventory management system. It will ensure inventory is kept up to date, reduces errors in counting and location, and automates processes such as put-away and picking. It can also support various dispatching configurations from small packages to full truckload shipments.Because an ERP integrates all business information, the counts of various inventory items is automatically shared with the purchasing department which can then make more informed decisions on when new orders need to be placed. - Quality control

Automotive OEMs and other customers demand extremely high levels of quality control and precision so distributors must be able to adhere to some stringent standards.Automation of the receipt inspection process makes sure that the quantity and type of items received match the purchase order. A configurable inspection capability will allow a distributor to customize an inspection system to their requirements so that quality standards are met and quality checks are done when items are received or shipped. - Traceability

Traceability is a major business need in the automotive industry. This is to enable tracking in case of a failure and also to provide full control in case of recalls. Recalls are becoming a greater risk in the industry with data revealing that European automotive recalls increased by over 30 percent in 2022.Automotive distributors need traceability and recall capabilities that can offer full visibility throughout the supply chain — from R&D, through materials handling, to assembly and shipping. This ensures quality and compliance with regulatory requirements. Traceability must provide the ability to trace, identify, isolate, report, quarantine and place affected products on hold quickly and with minimum disruption. - Managing returns

Associated with quality control and traceability is the need to provide an easy and efficient method of controlling the return or exchange of items sold to customers. An ERP for automotive distributors should ensure the visibility and tracking of the returned item until the transaction is concluded. The ability to analyse returns is important to identify trends in returns for particular items which could indicate quality issues.Returns to suppliers should include processes to update other functions, such as accounts payable, purchase orders, and inventory control. - Manage customer demand

Automotive distributors who supply OEMs need to synchronize their supply with customer demand to prevent line stoppages in OEM plants. This involves automating order processing and other processes in the supply chain to reduce response times, supply errors, and prevent penalties from OEMs for production delays. - Sales order management

Distributors can enhance customer service through a fast, efficient quotations and sales order process that guarantees accurate and timely order fulfilment. This requires real-time access to information on stock availability, prices and product substitutions.For OEM customers, this also will include handling call-offs against contracts. - Cost management

In a competitive environment with fluctuating material costs, cost management is essential in maintaining and improving profitability. Distributors must be able to deliver high-quality components at competitive prices.Using an ERP for automotive distributors will give the finance department visibility into costs and profits across the business. This will help to identify issues such as variations between expected and actual costs, and slow-moving or excessive inventories.

Benefits of an ERP for automotive distributors

An ERP system for automotive distributors streamlines processes, enhances efficiency, and improves customer service. It offers real-time data insights, optimizes inventory management, reduces operational costs, and enables better decision-making. This leads to increased productivity and a greater competitive edge.

1 thought on “ERP for Automotive Distributors”

This blog highlights the critical role ERP systems play in addressing the unique challenges faced by automotive distributors, such as traceability, quality control, and cost management, to ensure seamless operations.