The pandemic pushed manufacturers and distributors to rapidly shift gears, from addressing work-from-home policies to managing extreme swings in demand and uncertain supply chains. A 2020 SYSPRO survey showed that 60% of manufacturing and distribution businesses were impacted by supply chain disruptions during the pandemic. In fact, 29% of businesses stated they would explore initiatives to address immediate needs and accelerate digital transformation. For the manufacturing and distribution CEO the challenge is not only getting back to pre-pandemic operations, but crafting businesses that emerge more resilient than before.

Addressing industry pain points with ERP

The latest World Manufacturing Report, reveals that industries that adopted new technology started recovering faster from the pandemic, with increases of at least 10% in the first quarter of 2021, while low-technology industries registered a comparably lower growth rate of only 5.8%. The technology challenge is one that requires proactive action from the CEO. This allows for more than just catering to online customers and managing operations remotely, but an opportunity for organizations to run smarter, improve operations and efficiency which will make an impact to the bottom-line. Selection and deployment of ERP software can be a game-changer and provides CEOs the ability to build and modify business processes for success. Here are examples of the tangible return-on-investment (ROI) ERP can bring to your business:

- Maintain competitive advantage with ERP

Over the last year, those who were more robust remained resilient. From our research 67% of businesses stated that due to digital initiatives such as e-commerce, digital supply chains and remote working, they could continue to trade effectively during the pandemic. During the pandemic ERP kept industries in operation with its ability to sustain business operations through remote access to data, automated reporting, electronic data exchange, and real-time factory controls.

- Use ERP to improve operations and efficiency

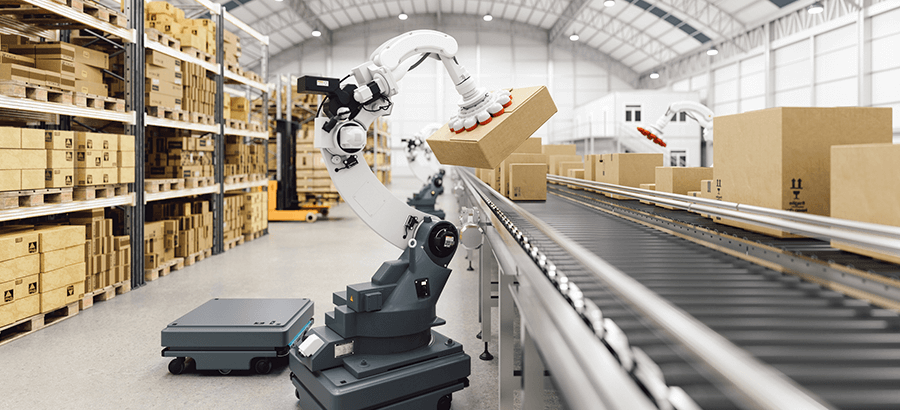

According to 2021 G2 ERP Statistics 95% of businesses achieve major improvements after using ERP through reducing process times, increasing collaboration, and centralizing enterprise data. ERP offers manufacturers and distributors the opportunity to integrate all their data into the same system which provides more precise production-floor monitoring, demand forecasts and information sharing. Companies can control inventories, avoid overproduction, and implement more cost-effective practices into their operations. Relying on disparate or outdated systems can really affect efficiency and your bottom-line. ERP reduces operational and administrative costs. For example, ERP makes it easier to account for stock and automates accounts for improved cash-flow.

- ERP to drive business strategy and insights

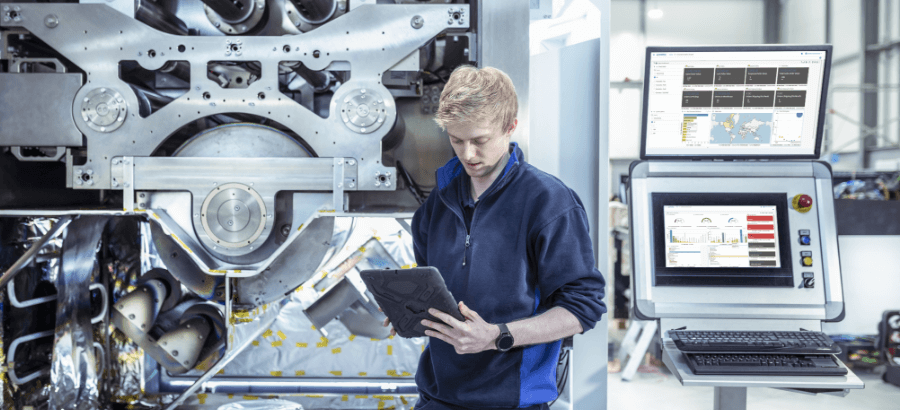

Initiatives that will meet your ROI as a CEO will be guided by and from the factory floor data itself. It is key for the CEO to not only identify new opportunities for automating and improving operations but use data to improve manufacturing and distribution performance. ERP offers end-to-end visibility of all key elements from financial, inventory to operations and sourcing. This will enable the CEO to act on this information and manage risks and make strategic decisions with favorable profit and cost ramifications. This will also empower the CEO to not only understand the business but customers better to scale and support business growth and new markets.

The next step for the CEO

2021 G2 ERP Statistics also reveal that about 28% of organizations achieved ROI within the first year of adopting ERP, and over half (58%) did so in less than two years. It’s imperative for the manufacturing and distribution CEO to understand that ERP provides tangible ROI allowing the business to expand into new markets, increase revenue, improve efficiency and agility, reducing risks all while strengthening customer relationships and producing high-quality products and services.

Taking your manufacturing or distribution organization to the next level of growth requires a strong, integrated technology foundation, which includes a well-matched ERP solution from a trusted advisor. CEOs should take a step-by-step approach and be clear on business objectives and impact of these solutions. Don’t make the mistake of thinking investments in technology will automatically lead to changes in business processes. You will need to also put into practice process transformation to really see the results of digital transformation.

1 thought on “ERP ROI for the manufacturing and distribution CEO”