The effects of the Coronavirus pandemic are far from over and a recovery timeframe is anything but certain. Among the strategies that businesses are adopting during this time in order to keep costs in check and reduce the size of layoffs, is to focus on procurement to maintain ongoing supplies of materials and components, and to reduce the risk of unanticipated costs. Procurement is no longer the department that gets discounts and places orders, it now has increased strategic value.

Procurement can play a key role in addressing the supply chain and inventory challenges during the current crisis. From an operational perspective, though, there are everyday issues that procurement has to look out for. What are the common issues and what can procurement do to address them?

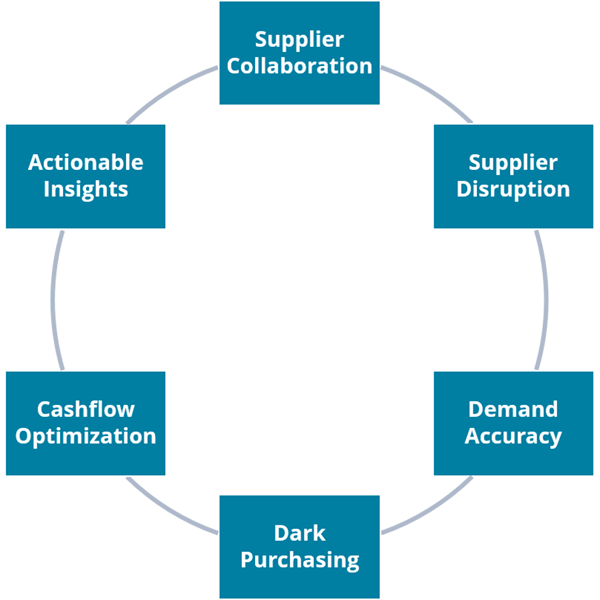

You can summarize the areas that procurement can start working on as:

- Supply

- Demand

- Management

- Dark Purchasing

- Cashflow Optimization

- Actionable Insights

Procurement Challenges:

Supply

The Coronavirus made people realize that supply chains were more fragile than they thought. Once those supply chains were interrupted, the immediate action was to contact suppliers to see how to get things moving or to find alternative suppliers. The second option then required more communication to agree and establish new contracts.

Traditional procurement practices for communicating with suppliers can be slow and inefficient. With modern online systems, the process is more streamlined and quicker.

What should you consider?

An online portal that encourages collaboration and engagement between buyers and suppliers, which also minimizes physical document handling, improves the buying process by making it quicker and more transparent and ensures greater reliability of fulfilment and delivery.

A request for quote capability tied to a supplier portal enables buyers to invite several suppliers to tender for the supply of items. In the case of supply chain disruption, this can speed up the process of fixing a broken supply chain and providers’ buyers with the agility needed to manage unreliable logistics or sourcing processes.

Demand

How procurement can improve its processes to make better use of inventory has been covered elsewhere . But in the area of customer demand, buyers can make use of other tools to make more accurate decisions about purchasing requirements. These tools include:

Inventory optimization to generate more accurate forecasting and planning of raw materials and components; and materials requirements planning (MRP) to help identify and order all the items necessary that production needs in time to satisfy demand.

Management

As well as revamping processes and adopting modern tools, aspects of procurement management, analysis and reporting can be improved to support organizational goals.

A problem for many procurement departments is the inability to track or control items purchased outside standard processes and approvals – so-called dark purchasing. One way to address this is obviously to have an accounts payable (AP) system that provides the necessary controls. But it also helps if the AP system is tied to a workflow process that automatically routes purchase requests to relevant approvers. An additional feature you can consider is to add artificial intelligence (AI) to the AP process which can detect anomalies and potential fraud.

An effective AP system also allows procurement managers to manage cashflow better. When AP is integrated with other systems in the business, such as manufacturing and inventory, it provides procurement with a much broader view of the factors that influence the health of the enterprise.

While improving processes and using appropriate software will make a difference in procurement’s strategic role in the organization, managers also need to have the information that tells them what goes on in the procurement department to ensure they are aligning with procurement and corporate objectives. This includes visibility into the supply chain and being able to collaborate with other functions in the organization to undertake whatever actions are required in a timely manner.

Procurement needs to be integrated

It’s all very well having the best procurement processes with the necessary governance and compliance, but if you operate in a silo that is not going to help the business. This is where an integrated business solution, like an ERP system, makes smart business sense. This integration enables the organization to get the procurement functionality they need, including flexibility, control, visibility and forecasting. And by integrating with other areas of the business, procurement’s role can become more strategic.

Download our infographic for procurement challenges