To deal with the new challenges in managing and planning the supply chain, the procurement department is one of the functions that should look at changing. It is no longer sufficient for procurement to focus just on supplier costs, placing orders and ensuring goods are received. Procurement in a post-pandemic world will need to take on a greater range of responsibilities with the assistance of technology.

There are several areas of procurement practice that should be considered for improvement:

Just-in-case

In the new normal where change and disruption can occur at any time, the procurement function needs to anticipate and plan for uncertainty. This means that the past practice of just-in-time inventory management will need to be more flexible and allow a just-in-case approach. Just-in-time focuses on having materials arrive just as production is scheduled to begin. Just-in-case involves holding more inventory so that sales are not lost due to inventory being unavailable. This is used for a potentially vulnerable supply chain and ensures goods can keep flowing in a manageable way.

Resiliency

To mitigate the risk of unexpected supply chain disruptions, sourcing strategies will need to be revised. Instead of cost reduction being the primary goal, the pool of suppliers should be broadened to provide resilience and backup, even though this has implications for material quality and control over costs.

In the past, the procurement department could work with a limited number of suppliers with locked-in quality agreements. The situation changes with a larger number of suppliers. The quality of goods received may not be as easy to control and procurement may not know about the quality of materials until they arrive. That is why it is so important for procurement to be integrated with inventory receipting and quality control, so that quality issues are immediately fed back to procurement for follow-up with suppliers.

Risk management

Risk management was not an issue that most procurement managers considered in the past. In an environment of volatility and uncertainty, risk analysis is becoming part of the procurement process. It’s not just the risk of poor quality from a larger group of suppliers, but going further down the supply chain to identify other actors that may impact the supply of goods or pose potential problems in terms of regulatory compliance or quality.

Supplier relationship management

Supplier relationship management is a way to align the people and processes that enable effective performance and risk management across the supply chain. It involves measuring supplier performance across a number of dimensions, such as on-time delivery, and material quality inspection. Again, it is not just focusing on cost, instead it should also include areas such as innovation, and adoption of technology.

The supplier relationship can also be improved with technology. A secure portal that allows suppliers to check orders and payments can assist suppliers in working with your company. By providing electronic Requests for Proposals (RFP) suppliers can respond to the changing needs of the company more quickly. An RFP can also be important for setting supply chain expectations.

Supply chain control tower

A concept that has gained attention as a result of recent supply chain problems is the supply chain control tower. The control tower provides real-time visibility of factors in the supply network. It does not necessarily involve new technology but can be incorporated into a dashboard that different functions can use. The benefits include:

- proactively managing supply chains in real-time,

- better planning,

- enhanced risk mitigation,

- increased responsiveness.

The Gartner research group has highlighted the benefits as:

- get real-time or close to real-time visibility and clarity,

- use and analyze signals,

- intelligently optimize responses,

- provide exception management.

Collaboration with Finance

Procurement should operate separately from finance but work with functions like accounts payable (A/P). In several companies there is now a Chief Procurement Officer (CPO). A/P can support procurement in areas such as payment and budgetary controls. But A/P should also ensure that procurement operates transparently and is aligned with company policies, procedures, standards. In turn, procurement needs to co-operate with the finance department’s working capital strategy and cash flow controls.

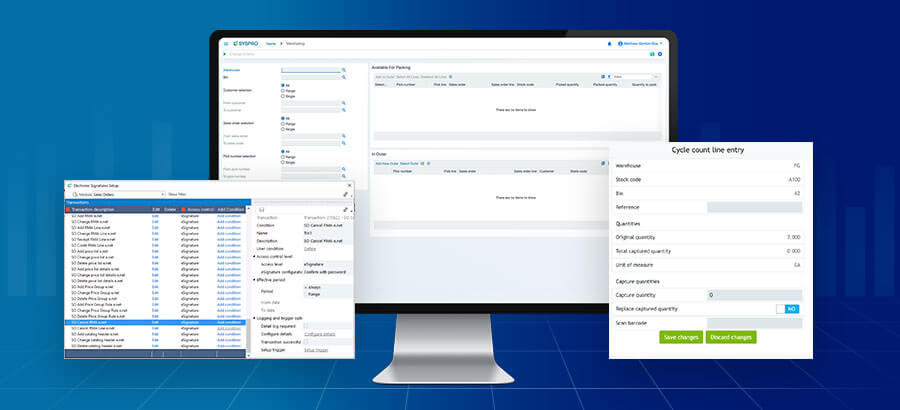

Procurement and A/P are jointly responsible for the processes of Source-to-Contract and Procure-to-Pay. For this co-operation to work effectively requires an enterprise system that integrates these processes so that different functions can work in a unified manner.

Metrics

The set of metrics used to manage and guide the procurement function should reflect its new responsibilities. These new measures will reflect how procurement should operate as part of an integrated organization. For example,

- inventory turnover,

- working capital,

- suppliers paid on time,

- supplier on-time delivery,

- material quality,

- risks assessment along the supply chain.

Digital transformation of procurement

The primary area for digitally transforming procurement to make it more effective is through automation and integration. An integrated and automated system allows:

- procurement and A/P to streamline the Procure-to-Pay process,

- procurement to get feedback from inventory management on receipts and material quality, and be aware of ABC inventory issues (how different categories of inventory contribute value to the business),

- procurement to work with production to improve how and when material is ordered for manufacturing jobs,

- suppliers to interact at any time with the business via an online portal.

The future of procurement in the enterprise

A procurement function that operates in a silo, separate from other functions, will lack the capability to make any substantive changes so that it can be more effective. Whether it is working collaboratively with other departments, working in a more volatile supply chain environment, enabling a more resilient supply chain through a larger group of suppliers, or managing risk, using an ERP system will allow procurement to deliver a more agile supply chain with visibility across the entire supply ecosystem. The ERP system can help mitigate risk, improve governance and provide insights into supply chain issues so procurement provides the value and services needed.

2 thoughts on “How the procurement role should evolve in the new supply chain”