Within African manufacturing organisations, there is a need to educate the industry on new technologies, what they are, and how they can be effectively deployed within their business operations.

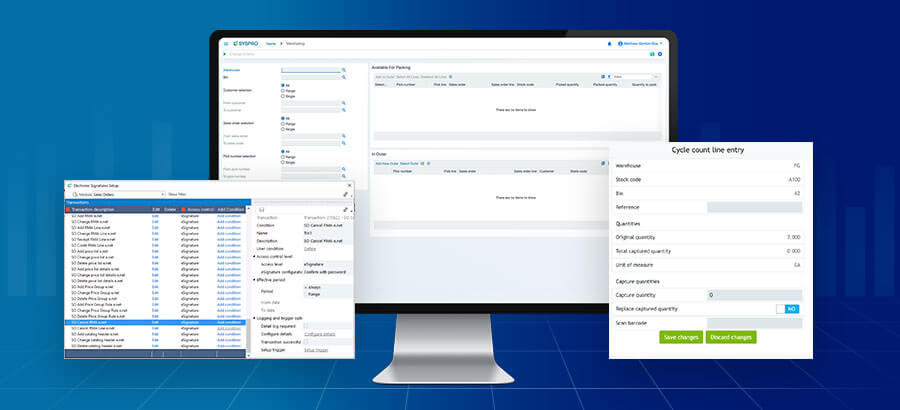

For years, manually inputted spreadsheets have gone hand-in-hand with ERP, which often result in manual capturing errors, and siloed information. There are a number of benefits in selecting a comprehensive ERP solution that can produce greater insights and negate the need for spreadsheets.

The benefits of automation

Businesses that embrace automation see a reduction in the costs associated with human error, as it relates to data inputs, miscalculated quotations based upon old exchange rate or vendor/supplier information, and procurement among others. As data is centrally stored, operational and financial reporting becomes simpler and more valuable.

Automation offers the potential to mitigate many of these risk factors and improve on the business’s overall effectiveness and productivity. By integrating automation, businesses can often see relatively rapid results, particularly in the areas of finance, supply chain management, production, and product innovation.

This presents opportunities for forward-thinking manufacturers to capitalise on and increase productivity. This will not only remove repetitive functions, but see several jobs and functions done more effectively and efficiently. With machines taking over the monotonous tasks, including basic accounting functions, manufacturers will see increased accuracy resulting in increased revenue.

Automation within the supply chain

ERP optimises processes across the business and enables visibility throughout the supply chain:

- Quotations based on accurate material, labour, and outsourced services costs could be quickly issued to clients.

- Planning would be based on more accurate projected demand and supply figures so you could create your production, purchasing and supply transfer schedules with greater efficiency.

- By plugging AI into ERP systems can reduce inaccuracies often felt throughout the supply chain, translating into better outputs for the whole business process.

- Leveraging ERP systems automation capabilities, automated operations are known to perform tasks more efficiently than manual operations, not to mention, increase the rate of production.

Enabling automation with industry-built solutions such as SYSPRO ERP simplifies business complexities by providing an end-to-end solution for optimised cost control and enhanced business performance, positively positioning the industry for the next generation of manufacturing.

While the Fourth Industrial Revolution (4IR) brings many opportunities for the manufacturing industry, it brings many challenges too. Those enterprises that embrace automation, and extract maximum value from their ERP, will keep pace with the changes, and benefit from the insights gained from the resulting in-depth analysis of their business.

Setting strategy for buying, implementing and operating ERP

We have created an e-Book for you, that shows you how to drive ERP implementation through clearly defining what the ERP project is meant to achieve, and how organizations can pursue their strategic objectives.